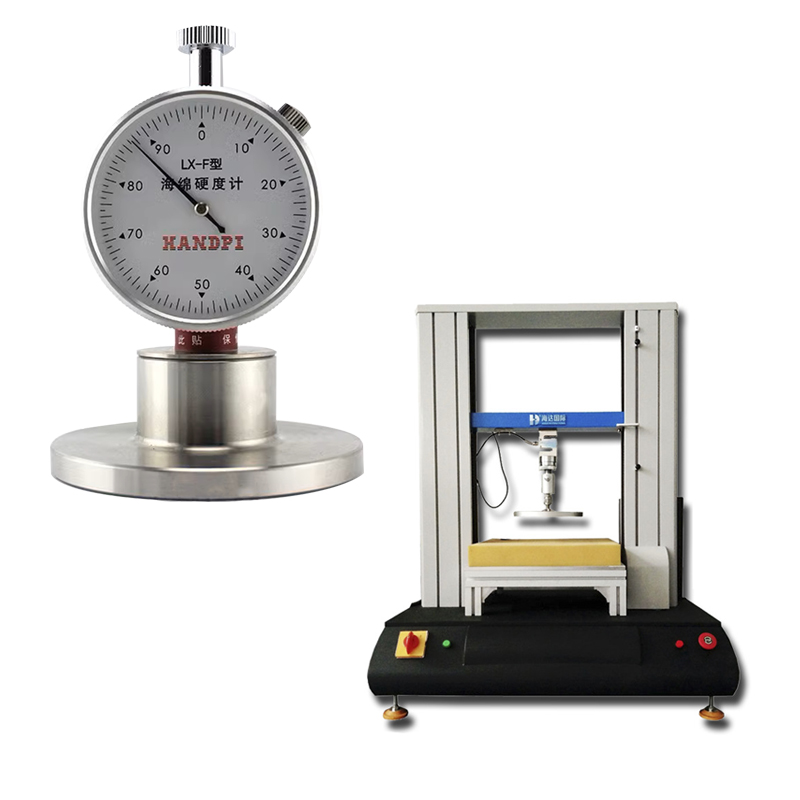

Sponge Foam Series Testing Equipment

Foam products are subject to high consumer demands for comfort and performance. Therefore, manufacturers must rely on advanced testing tools to ensure the quality and consistency of their products. Here are some devices used for foam product testing fyr.

What are the costs to produce rebonded foam? How about the advantage compares to other foams?

Rebonded foam is a type of foam produced by chopping up used foam scraps into tiny pieces and bonding them with an adhesive. This forms a brand-new foam item. Rebonded foam production and use involve several financial factors, including:

How can manufacturers ensure consistent quality and performance of different batches of rebonded foam?

By putting a strong quality control mechanism in place, manufacturers can guarantee consistent quality and performance across various batches of rebonded foam produced. Numerous processes are involved in this, such as: Inspection of raw materials: To ensure that the raw materials used to create rebonded foam fulfill certain quality criteria, manufacturers should examine the raw […]

What industries have the most promising applications for rebonded foam?

Rebonded foam is a made by waste pieces of PU foam. Because of its strength, adaptability, and affordability, it is used in a wide range of industries. The following are a few of the most promising uses for rebonded foam:

How do trends in the market for foam products impact the demand for rebonded foam?

Trends in the foam industry may have an influence on demand for rebonded foam. This is due to the fact that rebonded foam is a sort of recycled foam created from leftover PU foam.

How do you test and measure the performance of rebonded foam? What are the most important quality criteria to consider?

If you want to test and measure the performance of the rebonded foam, here are some testing methods for your reference:

What are the common misconceptions about rebonded foam? What are its advantages and limitations?

There are several common misconceptions about rebonded foam. To educate customers about the benefits and limitations of rebonded foam, you could:

What is the effect of foam skin on the quality of rebonded foam?

The hard skin on the PU foam can affect the rebonded foam quality. Here are some informations for your reference:

How does PU foam scrap affect the quality of rebonded foam?

The use of PU foam scrap as a raw material in the production of rebonded foam can affect the quality of the final product. Here are some effects of PU foam scrap on the quality of rebonded foam:

How to choose good quality of rebonded foam?

When it comes to choosing good quality rebonded foam, there are several inportant factors: density, bonding strength, uniformity, compression resistance and packing.