What is the difference between high-density and medium-density PU soft foam

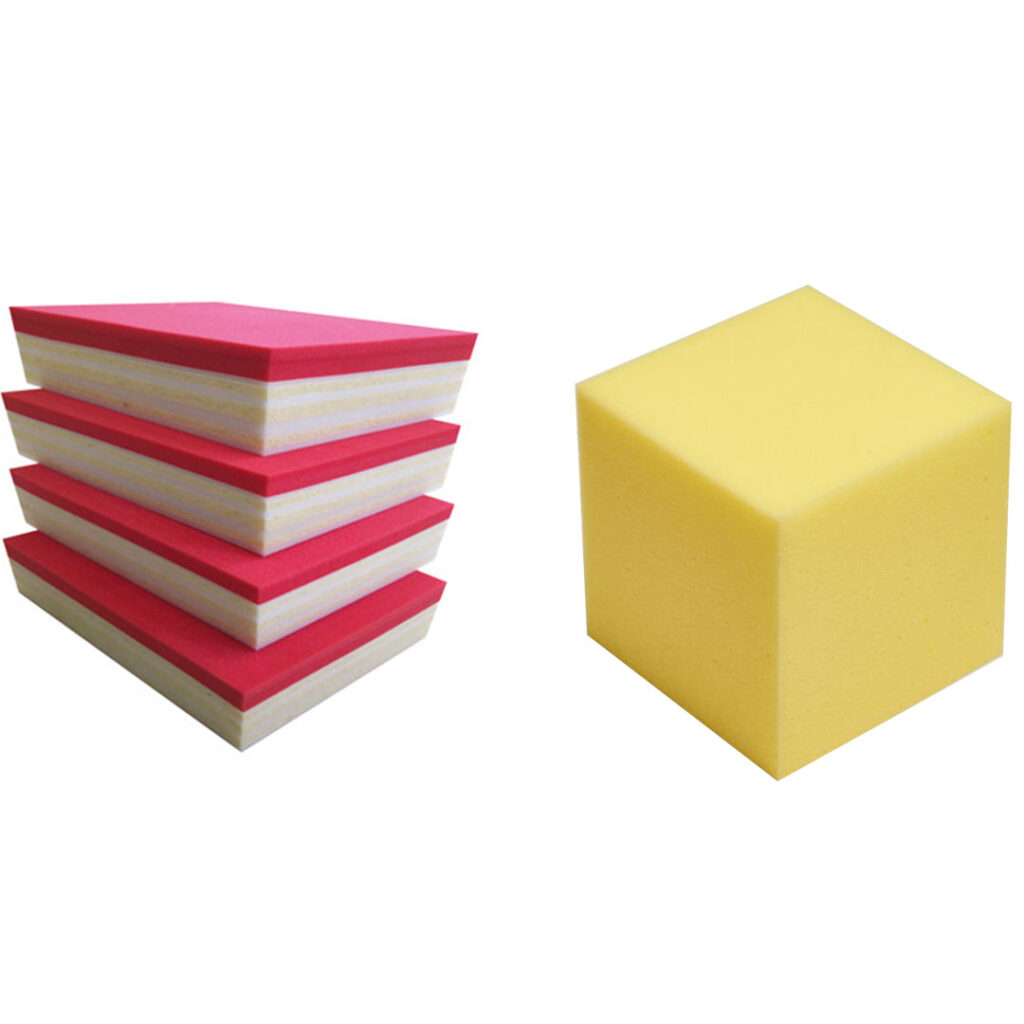

In the foam industry, PU flexible foams are grouped by density (KG/M3): high-density for sound absorption, sofa cushions, and soft packaging; medium-density for protection. High-density foam (≥45) with abundant pores is versatile, while medium-density foam (45-18) is widely used for protective purposes.

What is the difference between high-density foam and high-resilience foam?

The difference between high-density foam and high-resilience foam lies in density and structure. High-density foam, suitable for sound-absorbing cotton and soft packaging, has high density and greater mass. On the other hand, high-resilience foam, made with polyether polyols, boasts excellent resilience and breathability, primarily used in car seats and furniture. The two types differ significantly in principles, applications, and characteristics.

What are the factors that affect the resilience of PU foam?

Factors affecting the resilience of polyurethane foam include: 1. Cell opening rate; 2. Cell shape; 3. Cell pore size and distribution; 4. Polyether polyol; 5. Isocyanate; 6. Other factors.

Production Process and Principles of Polyurethane Foam

This article introduces the production process and principles of polyurethane foam, including main raw materials, synthesis principles, and the production process. It covers the characteristics of flexibility, elasticity, and water absorption in polyurethane foam, widely used in furniture and decorative industries.

The role of polyurethane defoamers and what foam problems can they solve?

Polyurethane (PU), a type of polymer, possesses a thermoplastic linear structure with good stability, chemical resistance, and resilience.

What are the two main stages of polyurethane foam formation?

The molding of polyurethane foam involves two stages: the foaming process and the curing process. The process from the mixing of raw materials to the cessation of foam volume expansion is known as the foaming process

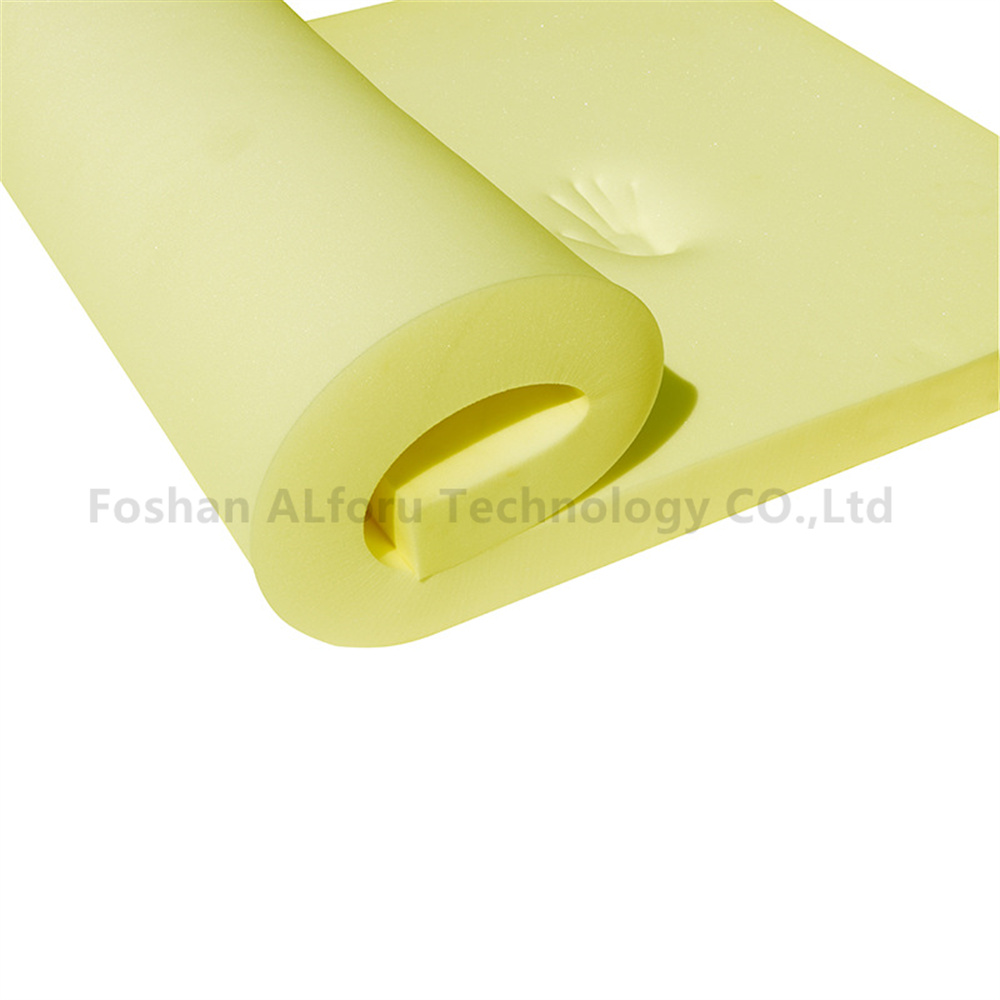

Production process and foaming formula for gas swelling slow rebound foam

Expansion slow rebound sponge is a type of sponge developed in the production of slow rebound sponge, utilizing temperature-sensitive and viscoelastic propertie

What equipments are needed to set up a sponge foam factory?

To start a sponge foam factory, what mechanical equipment do you need to understand? Let me briefly introduce the required machinery.

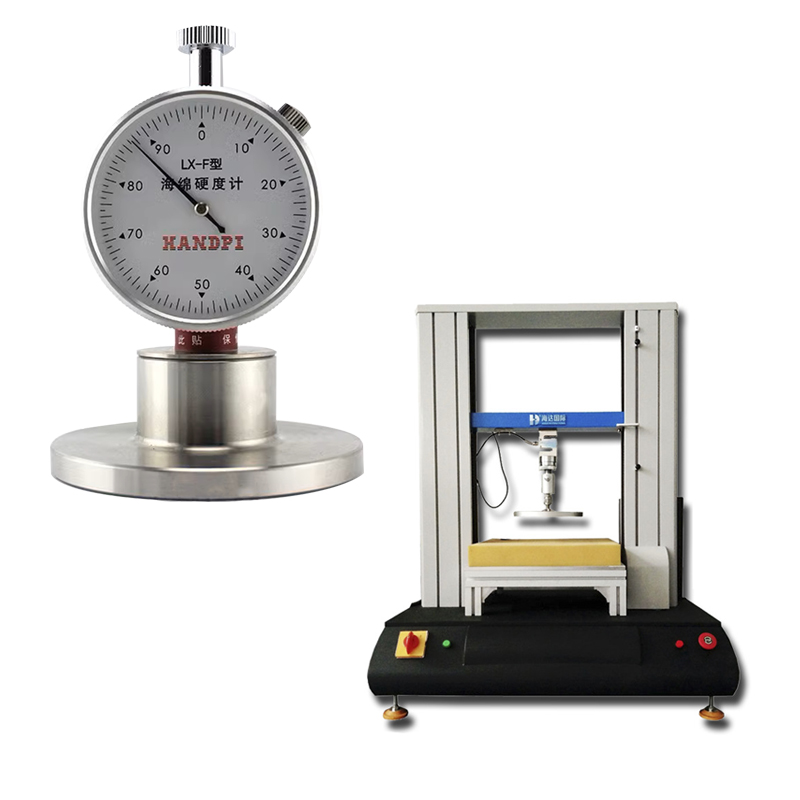

Sponge Foam Series Testing Equipment

Foam products are subject to high consumer demands for comfort and performance. Therefore, manufacturers must rely on advanced testing tools to ensure the quality and consistency of their products. Here are some devices used for foam product testing fyr.

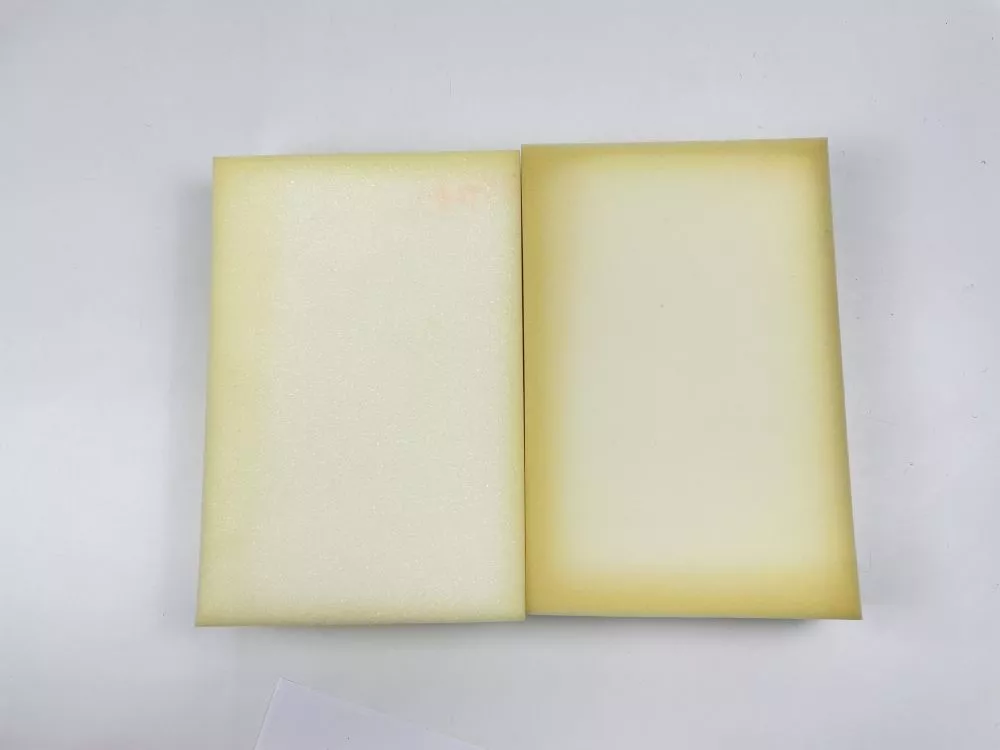

Causes and solutions for yellowing of polyurethane foam.

Yellowing in polyurethane foam can be attributed to various factors and falls into four main categories: