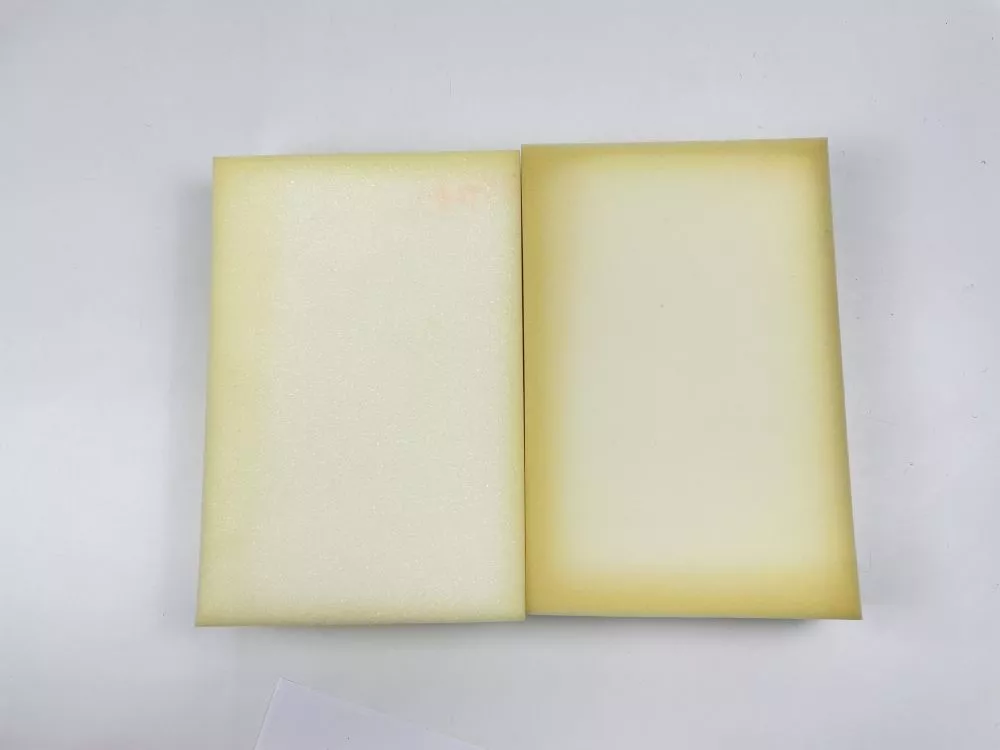

Causes and solutions for yellowing of polyurethane foam.

Yellowing in polyurethane foam can be attributed to various factors and falls into four main categories:

What are the raw materials of polyurethane foam?

Polyurethane foam(PU foam) primarily consist of polyurethane as their main component. The raw materials primarily include polyisocyanates and polyols, with the addition of various additives, the most crucial of which are a series of foaming agents related to the foaming process.

What factors contribute to the perceived firmness of polyurethane foam?

The apparent hardness of polyurethane foam is predominantly shaped by the following elements:

What is the ideal density for sofa cushions?

In China, a foam density of around 50 is considered good, as anything over 50 likely contains additives that you might not want in your foam.

Why is high-density sponge foam considered of superior quality?

Within the industry, sponge foam is typically classified according to its density. In the market, you can commonly find two primary categories of sponge foam: high-density sponge foam and regular sponge foam. These two types are easily distinguishable by their appearance and texture.

What are the typical types of catalysts used in polyurethane production?

Polyurethane synthesis and its associated materials generally employ two main categories of catalysts: tertiary amine catalysts and organometallic catalysts.

What are the common polyurethane flexible foam on the market?

There are many different types of polyurethane flexible foams on the market, following are a few popular varieties types for your reference:

How to choose good quality latex foam?

Numerous aspects need to be taken into account when selecting high-quality latex foam. Here are some recommendations to assist you in choosing premium latex foam:

What are the costs to produce rebonded foam? How about the advantage compares to other foams?

Rebonded foam is a type of foam produced by chopping up used foam scraps into tiny pieces and bonding them with an adhesive. This forms a brand-new foam item. Rebonded foam production and use involve several financial factors, including:

How can manufacturers ensure consistent quality and performance of different batches of rebonded foam?

By putting a strong quality control mechanism in place, manufacturers can guarantee consistent quality and performance across various batches of rebonded foam produced. Numerous processes are involved in this, such as: Inspection of raw materials: To ensure that the raw materials used to create rebonded foam fulfill certain quality criteria, manufacturers should examine the raw […]